How to Streamline Your PCBA Process for Maximum Efficiency

Streamlining your PCBA process is important for making things run smoothly. First, it’s crucial to plan everything carefully. Start with a clear design. Make sure you have all the details right before moving to the next steps. If the design is solid, it saves time later. At Engine, we use advanced software tools to help with this part. These tools help us catch mistakes early on, which can save a lot of hassle.

Next, communication plays a big role. Everyone involved in the process, from designers to manufacturers, must be on the same page. We encourage regular meetings and updates. This way, if any issues pop up, they can be addressed quickly, preventing delays.

Another key point is using the right materials. Choosing high-quality parts ensures that the final product is reliable. Engine works with trusted suppliers to get the best components. This helps avoid problems down the line. Additionally, we focus on automation. By using machines for certain tasks, we increase speed and reduce human error. While machines do a lot of the work, our skilled team is always there to oversee everything.

Finally, once the PCBA is complete, testing is vital. We have specific tests in place to check if everything works as it should. This step is essential to catch any mistakes before sending products out. By following these steps, businesses can enhance their PCBA process, making it more efficient and effective.

Finding the Best Quality at Competitive Prices

Getting the best quality at competitive prices is a big challenge for many companies. At Engine, we understand that businesses want great products but also need to manage costs. One way to achieve this balance is through strong relationships with suppliers. We work hard to build connections with high-quality material providers. These relationships allow us to negotiate better prices without sacrificing quality.

Another aspect is keeping a close eye on production efficiency. By using smart manufacturing techniques, we can reduce waste and cut down on unnecessary expenses. This means we can offer lower prices while still making sure every product meets our quality standards.

Moreover, we invest in technology. New machines and software can speed up production and lower costs. For example, automated systems can help with assembly and testing, which means we need fewer workers for those tasks. This doesn’t mean we value our workers any less. Instead, it allows them to focus on more complex tasks that require human skills.

It’s also important not to forget about feedback. Listening to our clients helps us understand what they need. By adjusting our processes based on this feedback, we can continue to improve and offer the best possible service. At Engine, we believe that quality and affordability can go hand in hand. By focusing on relationships, efficiency, technology, and communication, we help our partners find the best solutions for their needs.

What Are the Common Usage Issues in PCB and PCBA Production?

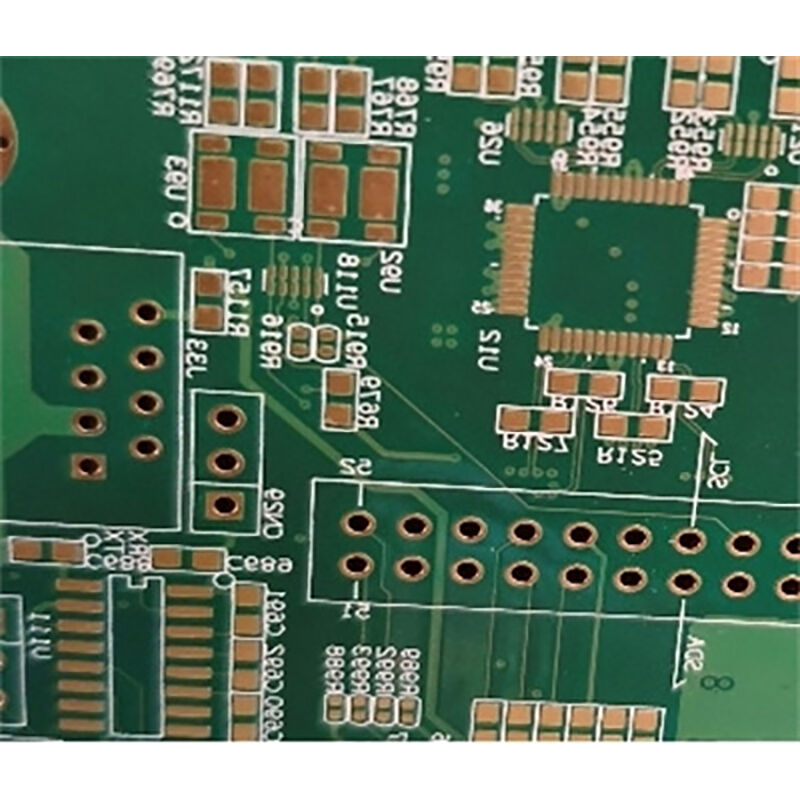

When creating printed circuit boards (PCBs) and printed circuit board assemblies (PCBAs), there are several common problems that can happen. One of the biggest issues is the quality of the materials used. If the materials are not good, the PCBs can break easily or not work at all. For example, if the copper that carries electricity is too thin, it might not let enough power flow through. This can cause devices to fail. Another issue is the design of the PCB. If the design is not done correctly, the parts may not fit well together. This can lead to problems like short circuits, where electricity flows in unwanted ways, causing devices to overheat or stop working.

Another common problem is soldering. Solder is the metal that connects different parts of a PCB. If the soldering is not done properly, it can create weak connections. This can make the PCB unreliable. Sometimes, tiny bits of dust or dirt can get on the board during production. These contaminants can cause issues too, like preventing the solder from sticking well. Other issues can arise during the testing phase. After making a PCB or PCBA, it is important to test it to make sure everything works. If there are problems during testing, it can delay the product and cost more money. These issues show why it is important to work with a company like Engine, which focuses on quality and careful production. By doing this, we can help technology partners avoid these problems and ensure their products work well.

Where Can You Find High-Quality PCB Assemblies for Wholesale?

If you are looking for high-quality PCB assemblies at wholesale prices, it can be tricky to find the right place. Many companies offer these products, but not all of them provide the same level of quality. One good option is to go online and search for companies that specialize in PCB and PCBA manufacturing. Websites like these often show reviews from other customers. Reading these reviews can help you see if a company is trustworthy. You can also look for companies that provide detailed information about their manufacturing process, as this often indicates they care about quality.

Another great way to find high-quality PCB assemblies is by asking for recommendations from people in the technology industry. If you know someone who has experience with PCBs, they can tell you which companies they trust. Attending trade shows and technology fairs is also a smart idea. These pcb events allow you to meet different suppliers and see their products firsthand. You can talk to them about your needs and ask questions. At Engine, we are dedicated to providing high-quality PCBs and PCBAs at competitive prices. We focus on building strong relationships with our clients and ensure that they receive the best products for their projects. By choosing a reliable supplier, you can be sure that you will get the best value for your money.

What Makes a PCB Supplier Stand Out in a Competitive Market?

In a competitive market, several factors can make a PCB supplier stand out from the rest. One important factor is quality. A supplier that consistently produces high-quality PCBs and PCBAs pcb circuit board will build a good reputation. This means they pay attention to details, use the best materials, and have strict quality checks in place. Another factor is customer service. A great supplier listens to their customers, understands their needs, and provides support throughout the process. This means they are easy to reach, answer questions quickly, and help solve any problems that arise.

Additionally, innovation plays a big role. A supplier that keeps up with new technology and trends can offer better products and solutions. This can include using advanced manufacturing techniques or offering a wider range of options for customers. Price is also important, but it should not be the only factor. A supplier that offers good value for money, without compromising pcba circuit board on quality, will be more appealing to businesses. At Engine, we strive to stand out by focusing on all these aspects. We are committed to providing high-quality products, excellent customer service, and innovative solutions. By doing this, we help our global technology partners succeed in their projects and create amazing products.